PRODUCT VIDEO

ABOUT

FAQs

INDUSTRIAL SEALANTS

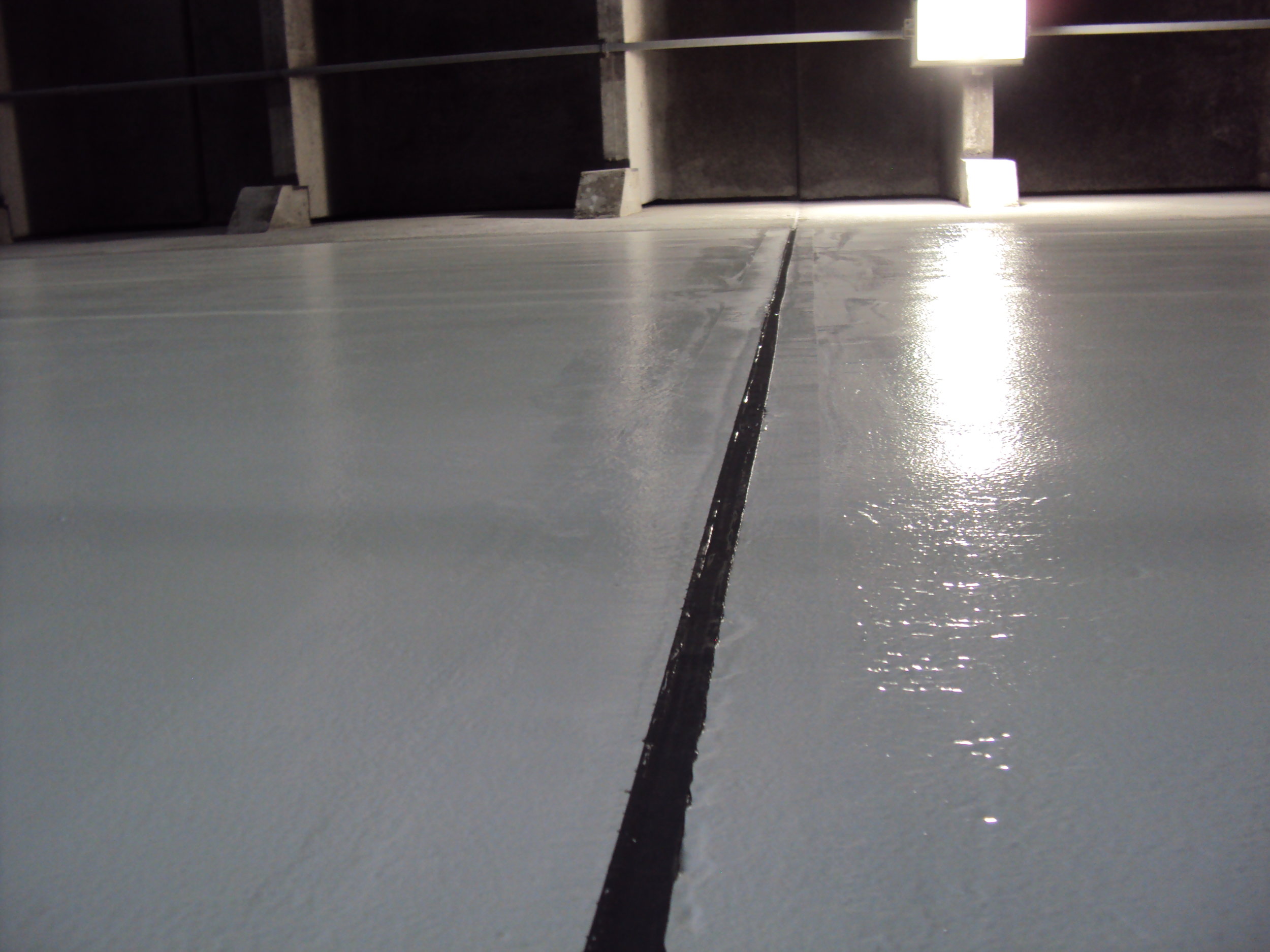

Standard Polymer’s line of industrial sealants contains fast-acting and extremely durable products. They provide long-lasting flexibility and protection under the duress of internal or external environmental factors, and other stressors maintaining their integrity for years. Applying the correct joint sealant and expansion joints to your inelastic surfaces introduces the flexibility needed to add longevity to the surface, keeping dollars in your maintenance budget.

Pliant enough to accommodate normal diminutive movements, our sealants are strong enough to hold up under heaving loading.

Vital for use in many industries, our sealants work their magic for your industrial floors, tank linings, secondary containments, cold storage, roads, and many other applications. The sealants’ long lasting resistance to temperature, weather and other environmental conditions will quickly convince you of their value to your operations and maintenance planning.

We can recommend the correct sealant for your concrete cracks, joint repair work or your new construction. Contact us for more information or for a personalized quote for your project.

FAQS

Why are industrial sealants an important part to a properly installed coating system?

In flooring systems and containments, it is always best practice to “honor” any and all expansion joints in the concrete substrate. Allowing the slab to move as it was designed to will limit any potential cracks from forming due to the slab having the ability to move. In food processing areas especially, a properly installed sealant in joints will eliminate areas of harborage by either pest and/or bacteria as well as eliminate areas for water from wash down procedures to sit stagnate. Sealing around tank chines will ensure any and all leaks from the vessel will make its way to the coating on the floor/containment and then into the drains. If this is not properly sealed, the commodity (corrosive material) could make its way between the tank floor and tank pad potentially creating voids in the concrete substrate as well as corroding the often unprotected bottom of the tank.

What are some of the important points to consider when choosing a sealant?

There are numerous types of sealants out there as there is not one product to fit all applications. Some of the more important questions to ask yourself are: What are the chemical exposures in this area? What are my temperature exposures that I will be seeing? What will this area see in terms of traffic (foot traffic, fork truck traffic, semi-truck traffic, etc.)?

Aren’t all sealant applications done using the same procedures?

There are just as many application procedures of industrial sealants as there are sealants themselves. It is very easy for a contractor to have the one “go-to” product that simply comes out of a caulking tube with a manually operated hand held caulking gun. While this works great for some of your basic residential and light commercial needs of applying silicone around windows, doors, sinks, etc., a one component sealant is more than likely not suitable for use in industrial settings. Most sealants used will be a two component material that can be applied by way of a margin trowel, hand held caulking gun with a “sausage tube” style gun, bristle brush and or roller. On larger projects with an excess of linear feet to be sealed, a pneumatic application gun attached to a plural component style pump may be used for efficiency.

I have used sealants in the past on both expansion joints and tank chines yet the sealant never seems to hold up? There will be caulking on both sides of the joint, why is that?

It is imperative that the joint is treated properly. By that I mean whether this is an expansion joint on the floor or a tank chine the void needs to be filled with a non-binding material such as foam backer rod prior to applying the sealant. We only want to have contact on two sides of the joint, not three. If we are adhered to more than two sides, the material will not be able to move and flex as designed and will pull apart from both sides of the expansion joint/tank chine. There are applications and detail diagrams available that typically show the “hour-glass” application of tooling the joint material out to maintain maximum contact as well as elongation.

Where can industrial sealants be used effectively?

In virtually any industrial application from chemical plants, grain milling facilities, food process plants, ethanol facilities, power plants, warehouse floors, etc. There are needs for sealants in any and all of these industries from flooring, containments, tank chines, CMU block walls, concrete wall panels, maintenance repairs to flooring/containments, around static load pads, sealing joints along drains, etc.

What kind of support can I expect from your involvement should we reach out with issues related to industrial sealants?

We would be more than happy to help make the proper material recommendation based on the above listed variables to consider. We would also help by creating a specification to be followed during installation to ensure a properly installed job. When it comes to the installation, we could help work with plant maintenance personnel to properly train them or recommend outside contractors that we work with on a regular basis to provide an installation quote for them to do the install.