Product Videos

Stainless Steel Manufacturers Dip Tank Lining with Vinyl Ester MGR UHC

ABOUT

FAQs

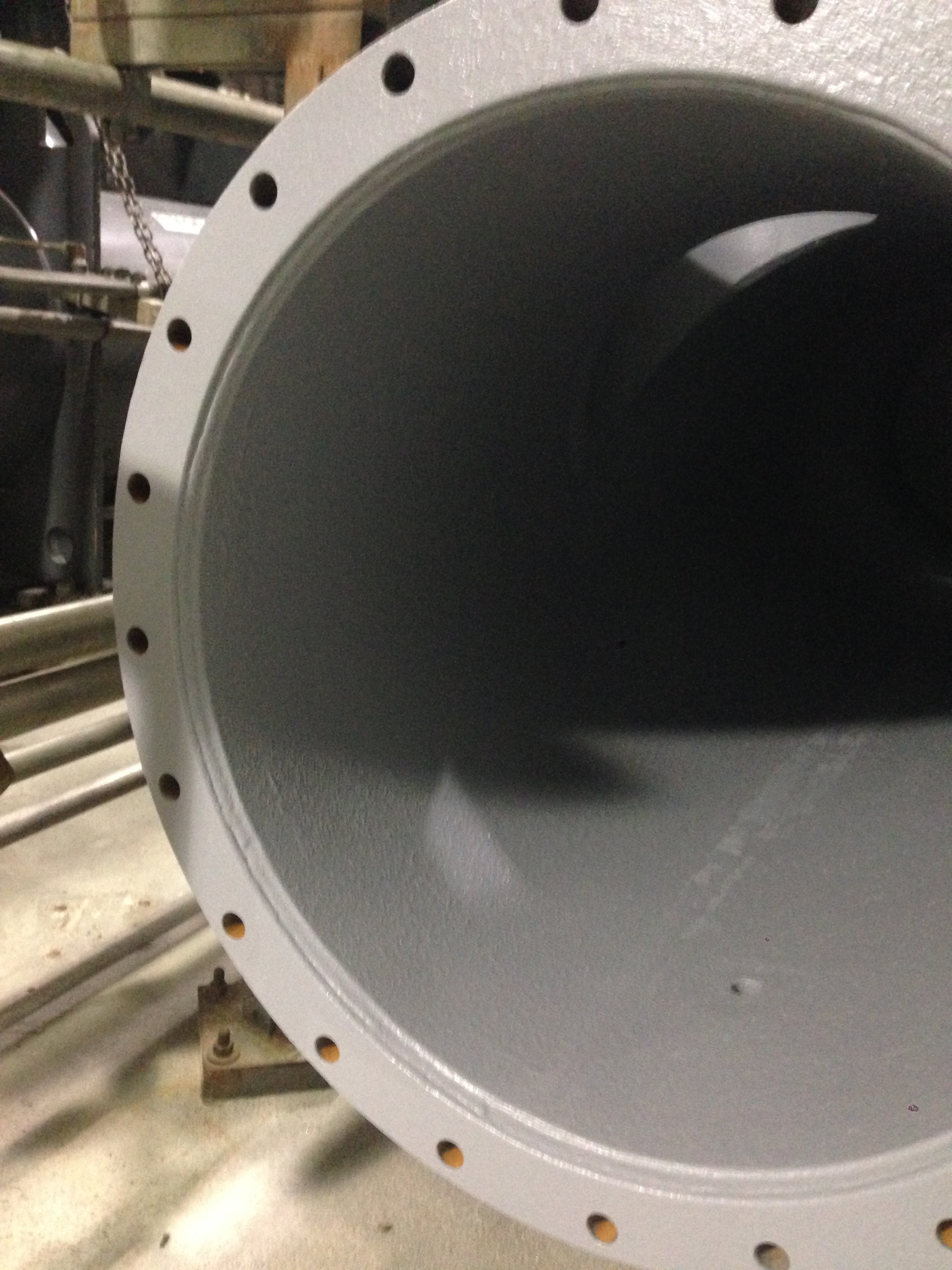

Tank Linings

The team at Standard Polymers has extensive experience with tank linings. We understand the unique features of lining projects. Unlike most coatings jobs, once a tank lining is complete, you don’t see the finished product. The integrity of the project is vital because it’s an “out of sight, out of mind” installation that you can’t just walk by and see in a maintenance check. You shouldn’t have to think about them again for several years and the right coating is key to giving you that peace of mind. Experience is so important in this type of project – our experience in providing the coating recommendation, a contractor experienced in surface prep and applying the material, and tank lining material with proven performance that not only meets, but exceeds government standards.

New tank linings or relining an existing tank are a necessary but pricey line item in your budget. A lining failure can take a costly hit on that budget that is to be avoided if at all possible. That’s where the expertise we offer within our company and the quality of tank lining material we offer will make the difference, preventing foreseeable problems and providing you with the confidence you want and need. We can evaluate your project to determine just which lining materials provide the correct characteristics for your new lining or have the right formula to provide the solution to your re-lining project. Our linings go on quickly and easily and provide the long-lasting performance you need. Our products are designed for tanks in various industries including chemical, pharmaceutical and food.

One very important consideration when making your choice of tank lining products is for you to be aware of exactly what government standards your product options have earned. Because of our history and experience working in the industry with these types of linings, we knew there was a huge need for a better product and a need for education amongst our customers. Knowing the difference between the terms used to label products is vital. **Do not be sold on lesser products because you aren’t aware of the difference in meaning in these terms.** Most products say they are “FDA Compliant” or “FDA Approved”. These two standards could mean many things. The typical definition would be that the manufacturer complies with government requirements for what goes in their formula. These are broad terms that typically are used quite liberally. There is also “USDA Compliant” and just about anything will pass that criteria, but the term sounds good. You rarely see products that have earned the same approval our line has. We have materials that were specifically designed for tanks in the food industry and have gone through all the government testing and certification required to earn the term “FDA TESTED” (a rare designation you don’t hear much in this market) making it the optimal product line for use in your food tanks. Don’t make the mistake of buying into a pitch for products made to a lesser standard for your important job.

Whatever type of tank lining you need, you can be assured that Standard Polymers will recommend and provide the optimum materials for you.

Contact us for more information or for a specific quote for your tank lining project.

FAQs

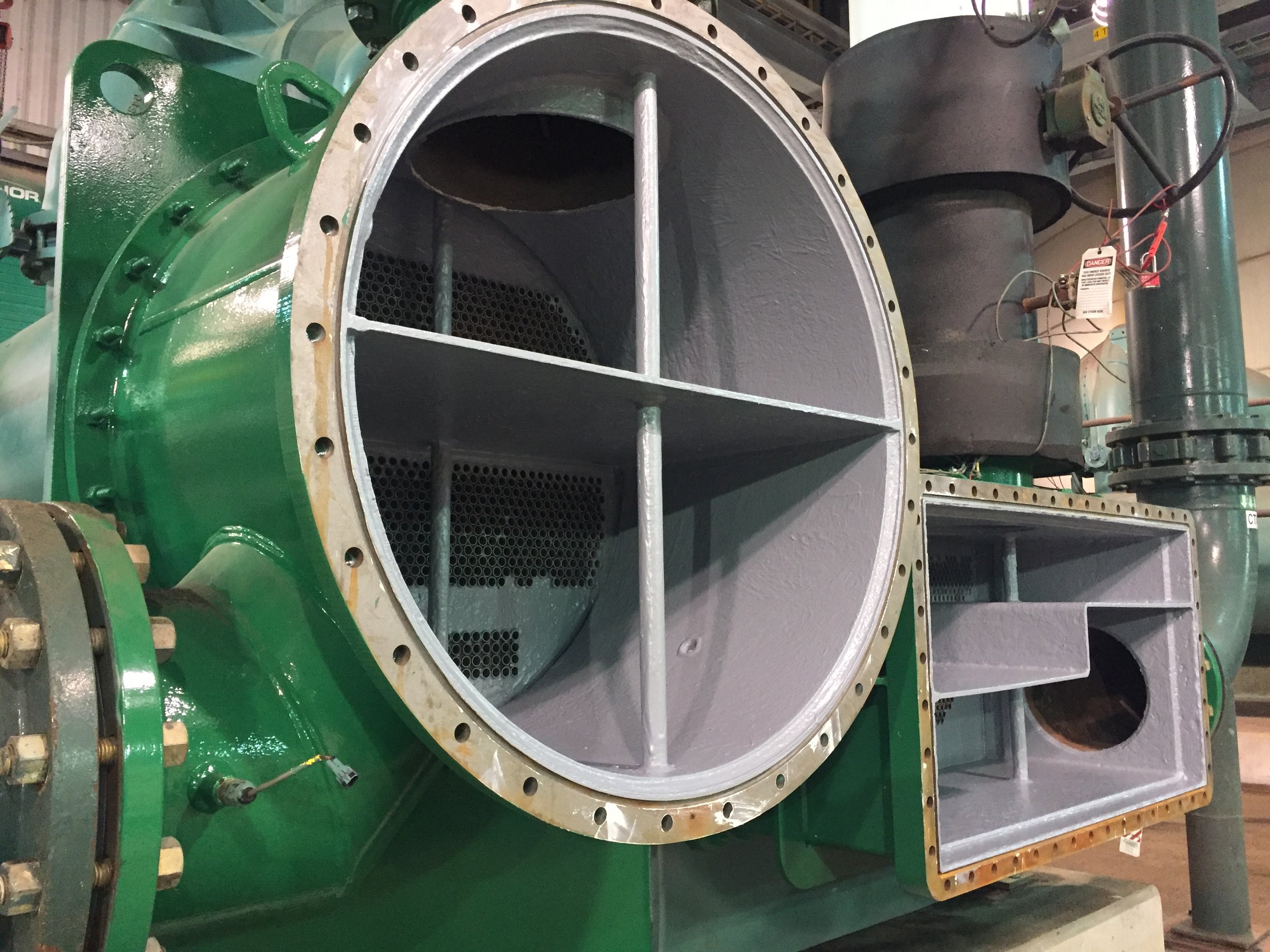

What is the purpose of a tank lining in a pressure vessel?

The majority of pressure vessels are manufactured from carbon steel which is very susceptible to rust when exposed to cold or hot water. The lining protects the tank.

What kind of tanks need to be lined?

Almost every kind of storage vessel needs a lining. We can supply FDA and NSF approved linings for potable water and food quality tanks as well as concrete, bulk dry-storage or steel tanks, pipe linings and tankers.

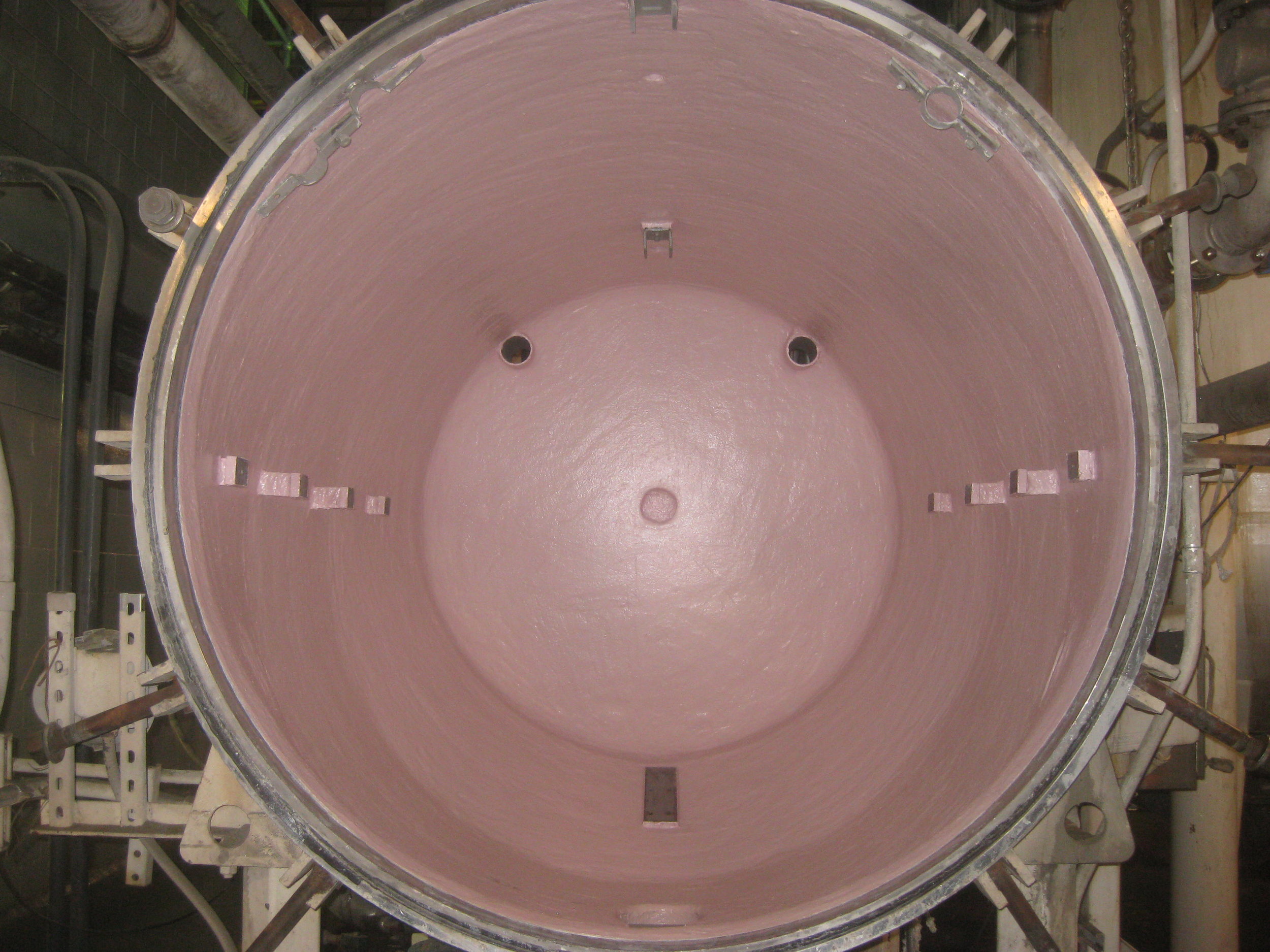

Can older tanks be re-lined?

Yes, older tanks may show the effects of time but they can be re-lined to extend their service life. Chemical corrosion over the years can damage the integrity of the tank but a new lining can not only protect the tank from further corrosion but function as well to stop contamination of the tank contents.

What causes tank lining failures?

A failed lining takes a catastrophic hit on the budget, production and time. Finding contaminants in your tank contents or a leak in your tank is a huge stressor. Improper preparation of the surface may be responsible for the failure of the lining material to adhere. Procedural errors like improper control and awareness of the humidity and temperature may cause create an environment where the lining cannot properly adhere or dry. Application errors such as not leaving enough cure time between coats can precipitate solvent entrapment. A lack of ventilation or not following required procedures post-cure can cause issues prompting a failure.

What is the crisis in the Industrial and Municipal Waste Water industry?

Over the years, standard protocol for maintenance or re-lining wastewater tanks and containments was to recoat using an epoxy or other lining system at a very thin mil thickness. This was the beginning of a rapid downhill slide towards the failure of the tank. Presently, in our country, the amount of wastewater tanks nearing the end of their service life numbers in the thousands. Properly lined waste water tanks with newer, more advanced materials to an adequate thickness will provide a better barrier to the corrosive gases and liquids found in all waste water streams.

What forces affect aboveground petroleum tanks?

Fuel oil and diesel aboveground storage tank systems can be stressed from exposure to solar heating, expansion and contraction due to air temperature fluctuations, and other factors. Typically used coatings lack the flexibility to remain adhered to the tank, resulting in the lining disbanding from the substrate which then causes the disintegration of the integrity of the tank to begin. Oxidation generates in the areas that have become disbanded from the tank and then spreads throughout the tank. A strong yet versatile product is required to prevent these and other forces from degrading the lining.

What are the primary factors to ensure a successful tank lining project?

There are many components necessary to obtain the end results you are looking for. They start with a good specification and material selection which a NACE trained, well-informed coatings rep can assist with. An experienced contractor is a must along with regularly scheduled controlled inspections and attention to all the environmental factors at play, including weather and temperatures. Having good equipment on hand to use is important and proper surface preparation is vital to preventing failure. It’s imperative to follow all government environmental regulations so ground contamination from leakage is prevented. Because linings are not visible once installed, making each factor it’s own priority and following each step deliberately and carefully will help ensure a positive project.