Product Videos

ABOUT

FAQs

Technical Info.

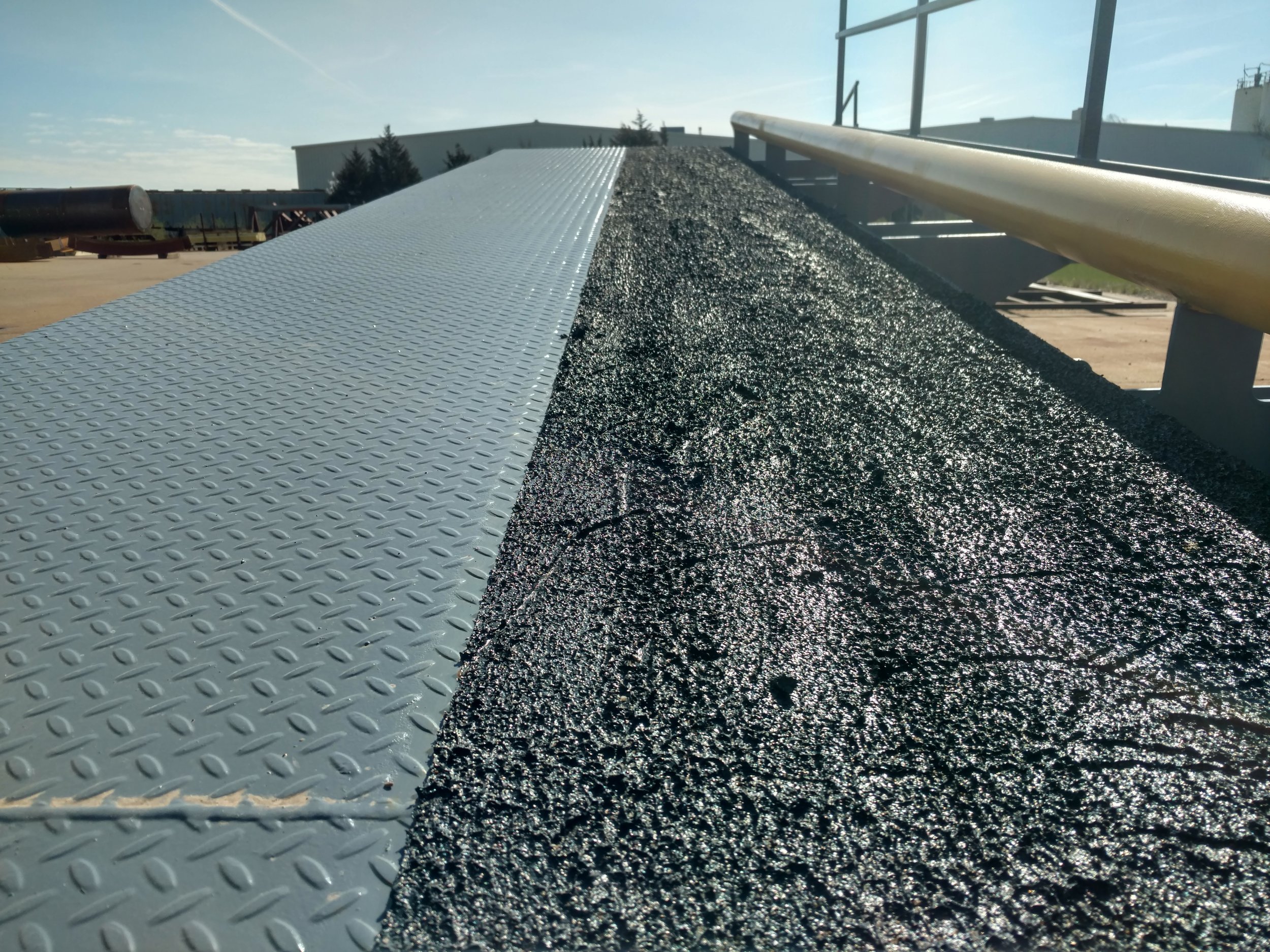

ANTI-SLIP COATINGS

The most recent data from the Bureau of Labor Statistics informs us that the 2014 U.S. workplace on-the-job fatality rate was the highest since 2008. That amounts to more than 13 people who died doing their jobs per day. The second leading cause of these fatalities was “slips, trips and falls”. The number of non-fatal injuries in this category annually also accounts for a huge portion of occupational injuries. According to the National Safety Council, the average cost of a slip, trip or fall accident is in the thousands of dollars. Not only are there direct operational costs to your company and impact on your staffing, the indirect costs of increased insurance rates and disability & workman’s compensation costs take another huge hit on your bottom line.

No matter the size of your worksite, no matter the size of your workforce, the safety of each employee is imperative. Preventing slips, trips and falls in the workplace improves productivity and morale and significantly lowers costs.

Wetness from rain or snow, slick chemical contaminants, food scraps or other detritus all create slippery flooring surfaces. Commonly sand is thrown into ordinary floor paint as a deterrent. This could be seen as a short-term “solution” but in actuality, it causes a further hazard as the sand crystals in the paint get rubbed or broken off and end up loose on the floor surface. The fix becomes part of the problem.

Standard Polymers provides tested anti-slip coatings that exceed the strictest OSHA, USDA and ADA standards. Our products are long-term solutions, lasting 5 times longer than the 6-9 month life-span of sand-in-paint. Specifically designed for extreme impact, chemical resistance and engineered to span the gamut of needs, our products withstand the wear and tear of heavy equipment and safeguard light pedestrian traffic. High traction is provided by the aggressive profile friction surface.

We can recommend an anti-slip coating tailored to the needs of your facility. We take into consideration the composition of the floor, weather, fire, water & chemical resistance, etc. From a locker-room to a food processing plant, from a confined area to a loading dock, from a hospital to a ship, our expertise will ensure you get the correct coating your surface requires.

Our anti-slip coatings cost per square foot averages the same cost as your ordinary industrial paints while providing your company protection from the unwanted dangers and unnecessary costs due to slips, trips and falls.

Contact us for a personalized recommendation and quote for your project.

FAQs

What kind of coating do you have available for a floor with very heavy traffic pattern?

Our recommendation would be dependent on your project and environmental factors and whether you’re referring to primarily pedestrian traffic or vehicular traffic. For pedestrian traffic, we have a very popular, easy to use, low-VOC, water-based product performs perfectly in that situation. Specifically engineered to be asphalt compatible and designed for pedestrian usage, it is also used over primed steel, on wood or concrete walkways, ramps and platforms. It comes in a variety of colors.

Another option would be a floor and deck coating with non-slip properties that adheres well to heavily used wood and metal concrete surfaces. It’s manufactured as a light-duty safety product. With job details in hand we could recommend the optimal material for your specifications.

Why shouldn’t I just use the old sand in the paint as a method of providing a non-slip surface?

Using sand mixed with paint as a non-slip agent is an outdated method which causes more harm than good. Gradually over time, contact causes the sand crystals in the paint to break or rub off leaving behind a residue that can cause slipping instead of preventing slips or falls. The anti-slip coatings we utilize are formulated to varying surfaces and processed to stand up to a range of traffic and are chemical resistant. They are tested and approved under government standards and last much longer than sand in paint. And they are not more expensive than paint to use so it just makes sense to use products manufactured precisely for providing a safer floor and a higher level of traction.

We need anti-slip flooring replacement material for our food packaging plant but the products we have used before have a strong smell. What would you advise?

There are standards in place and we have a Zero VOC’s product for those facilities where fumes and product odor would be unacceptable. It’s perfect for food & beverage processing plants of all kinds, commercial kitchens, hospitals and other facilities that fall into that category. It’s also ideal for use in small confined spaces. Standard or fast cure variations are available as well as low temp versions for refrigeration area or cold units. It’s strong enough to hold up to the effects of rolling heavy equipment and intense foot traffic as well as being resistant to the chemicals used in such facilities.

What about primer use?

Where appropriate, we recommend our sealing primer system for wood and concrete or the type of floor tile often used in commercial type kitchens or hospitals. Its formula was created to penetrate porous substrates which enhances the level of adhesion to the top coat.